Tribology: Optimizing Friction, Wear, and Performance

Tribology is the science behind mechanical efficiency and durability. It informs better design, smarter material choices, optimal lubricants, and effective surface treatments. By optimizing the tribological properties of critical mechanical components, overall system performance, service life, reliability, and maintenance costs can be significantly improved.

Tribology Platforms Driving R&D Excellence

At HEF North America, we operate two tribology R&D platforms:

Industrial Tribology Platform

Features a wide range of test benches, from standardized setups to custom rigs that simulate real-world conditions. These include high-temperature (up to 700°C), cryogenic, vacuum, and fluid environments and wear modes like fretting, corrosion, erosion, cantilevered joints, and fatigue.

Engine Tribology Platform

Focuses on enhancing engine efficiency through testing at multiple scales—from lab models to single-cylinder test benches.

3 Conditions of Tribology Testing

Tribology testing provides essential insights into mechanical component failure mechanisms, leading to performance improvements and cost reductions.

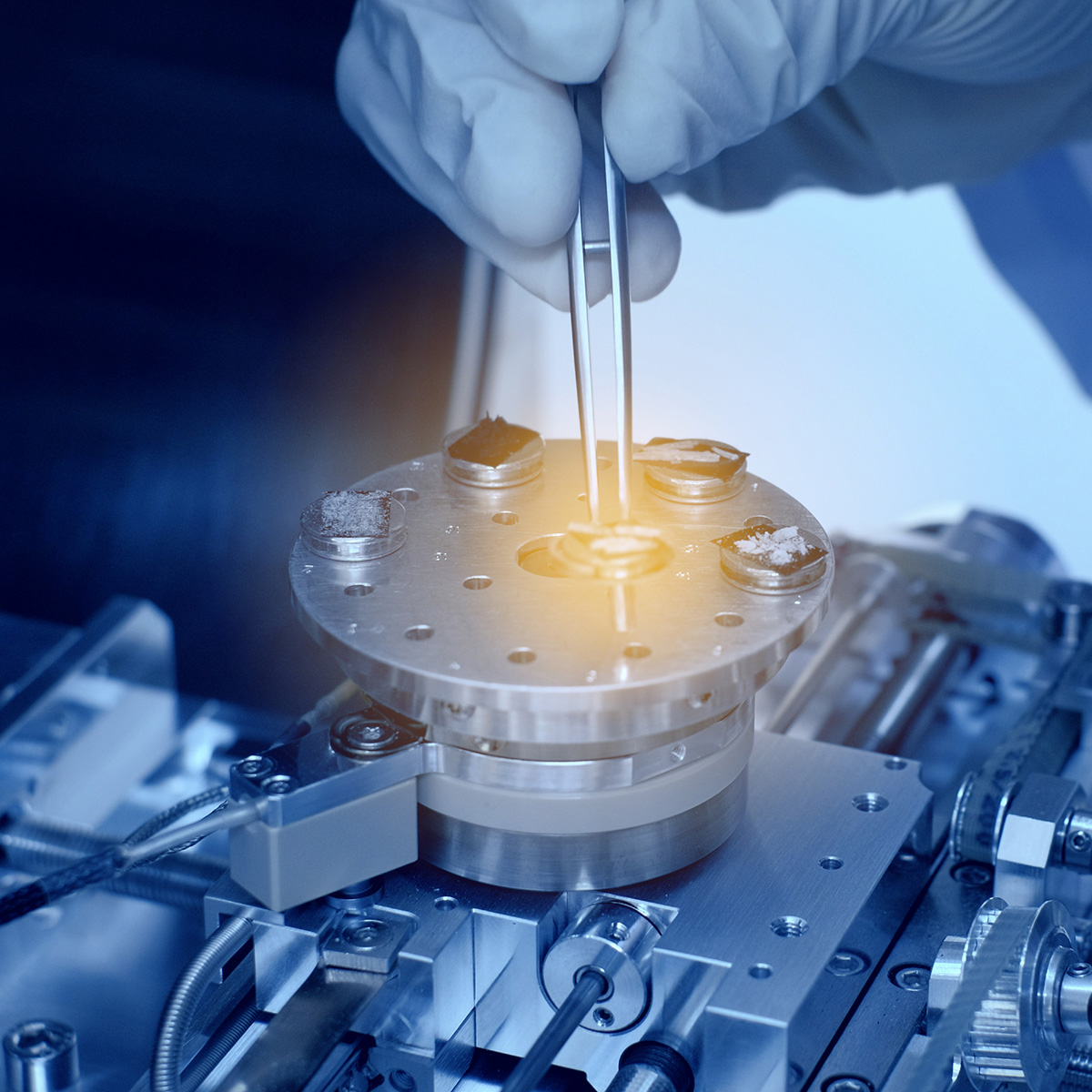

Sample Coupon Testing

Test coupons and counterpart parts—made from the same material and with similar surface characteristics as the actual component—are evaluated using standard tribology tests such as Falex Pin & Vee Block, Block-on-Ring, Amsler twin-disk, or Taber. Each method simulates the wear and contact conditions of the real application.

Component-Level Testing on Simulated Rigs

Actual components, sometimes modified to fit the test rig, are subjected to real-world wear and contact conditions. Variables such as velocity, load, lubrication, contaminants, and temperature can be adjusted to assess their effects on friction and wear.

Component-Level Testing on Actual Equipment

Performed within actual operating equipment (e.g., an automotive engine), these tests offer the most accurate real-world simulation. Instrumented systems track load, temperature, and other data to calculate friction, wear, and performance metrics.

Download the Tribology Brochure

Learn more about tribological solutions for different types of wear.

DownloadTribology Testing Capabilities

Our tribology work often begins with real-world problems—typically, a failed or worn part brought in by a customer. We analyze the damage to understand the root causes of degradation, which may lead to design modifications, material changes, or the application of advanced surface treatments.

Once potential solutions are identified, we move into an experimental phase to evaluate their performance. This involves carefully selected test methods and, when needed, the design of custom test benches. Our goal is to replicate actual operating conditions as closely as possible to validate results and ensure long-term reliability. The four types of tribology testing we perform include:

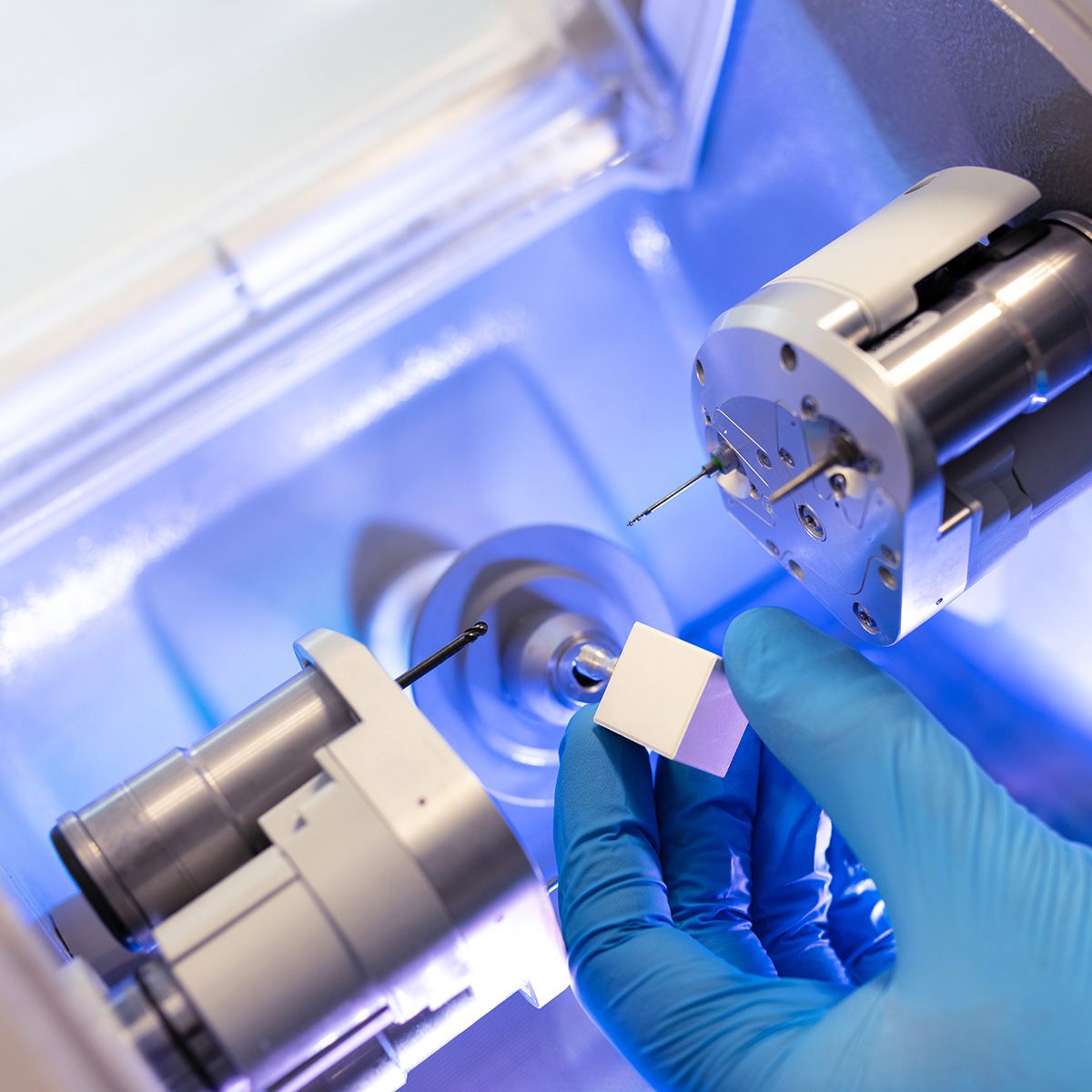

CALO Testing

Performed to check the coating thickness and ensure a uniform, consistent result. This test can measure the thickness of each layer as well as the total thickness of the coating.

Microhardness

Also known as nanoindentation, this test is performed on the coating to ensure the proper hardness is achieved.

Adhesion Testing

Also known as a Daimler-Benz Rockwell C indent test, it is performed on each batch of our PVD coatings to ensure optimum adhesion is being achieved.

Metallography

Used to measure the coating thickness of individual and multi-layer coatings and allows us to examine the interface of the coating and the substrate.