Polishing / Superfinishing

Precision Polishing for Smooth, Uniform, and Visually Refined Surfaces

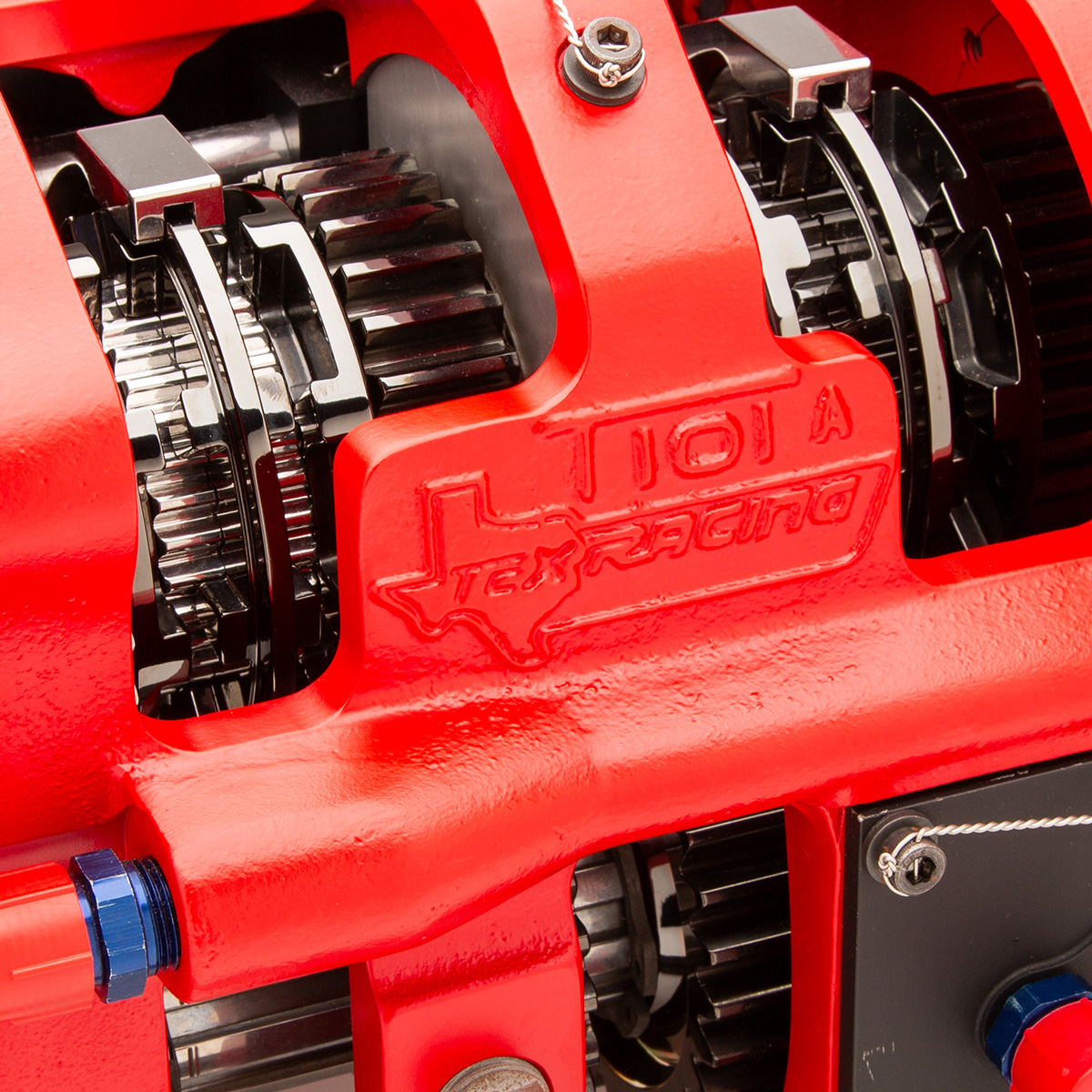

Superfinishing

Classic style vibratory polishing, also called Superfinishing, utilizes ceramic media with a mix of compounds and soaps. This style of polishing uses mechanical action of the ceramic or plastic media together with the abrasive material of the mixed compounds and soaps to create a smoother and more uniform surface than the original. The results of this process can be a surface with low roughness and visually more appealing.

The purpose of this polishing method is to knock down peaks on the surface through mechanical action. This happens with the polishing compound during the cut step of the process. After the cut, the parts are rinsed or burnished, removing the compound and cleaning the surface. This leaves behind a more uniform surface that may help with sliding actions that can also be visually brighter and more uniform than the original.

Isotropic Polishing

REM Isotropic polishing is similar to classic style vibratory polishing in its mechanical systems of polishing. The difference is that the REM system utilizes chemicals that react with the surface of the parts instead of compounds with abrasives. The overall idea is similar. The difference is, depending on material, the REM system can achieve a smoother, more uniform surface quicker and more efficiently than the classic style polishing.

Process Overview

Like classic style polishing, the REM system will knock down microscopic peaks on the surface, as well as remove machine lines and improve overall finish. This finish can improve the sliding friction as well as the visual aspect of the part. The process follows a similar flow to the classic style polishing.

- Step 1: Refinement

The chemistry reacts with the surface of the parts, forming an oxide. The chemical conversion of the surface to an oxidized state allows the soft oxide on the peaks to be mechanically polished away by the media, allowing the bare, exposed surface to be oxidized again—a process that can repeat several times. As the mechanical finishing by the media continues, it wipes the soft oxide layer away at the peaks but does not affect the valleys on the surface. When the refinement process is complete, the surface will have significantly reduced roughness and be ready for the final polishing phase. - Step 2: Burnishing

Neutralizes and removes the refinement chemical and produces bright uniform, polished finish on the product.

3 Types of Surface Finishes

Each type of surface finish offers distinct visual and tactile qualities, tailored to meet both aesthetic and functional requirements.

Matte finish: Achieved through sand blasting. Creates a rough but uniform surface to allow for a matte visual aspect.

Satin finish: Achieved through a bead blast process. Creates a surface smoother than matte but rougher than polishing that has a satin-like appearance.

Polished finish: Achieved through one or multiple polish processes, depending on the visual and mechanical needs of the parts.

HEF NA offers other application-specific Polishing / Superfinishing services.

For additional details, please contact us.

Contact Us