DLC Coatings

Superior Hardness and Ultra-Low Friction

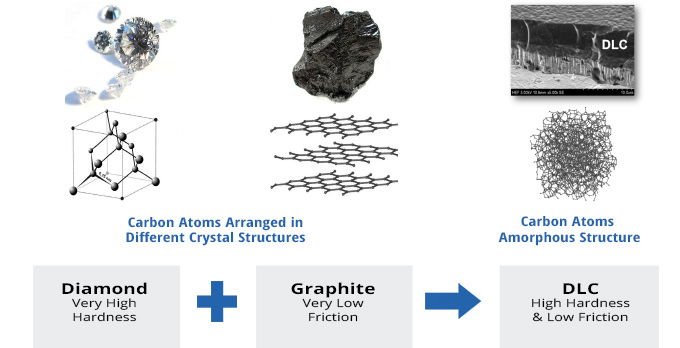

Diamond-Like Carbon (DLC) is a new generation of PVD + PACVD (plasma-assisted CVD) coatings that has gained widespread commercial success. Carbon can exist in three allotropic forms, two of which are used in DLC coatings:

- Diamond – One of the hardest known materials

- Graphite – Very soft and lubricious

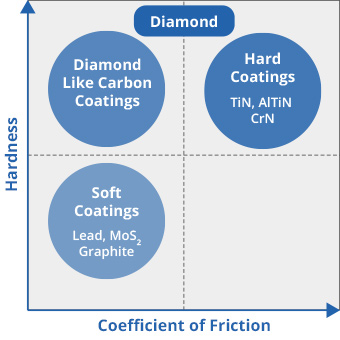

Carbon-based coatings, referred to as DLC coatings, combine the distinct properties of diamond and graphite. As a result, they possess high hardness levels—comparable to conventional tribological PVD coatings (1500–5000 HV)—while offering a coefficient of friction that is 200–500% lower than that of conventional PVD coatings.

HEF NA specializes in DLC coatings for high-volume automotive applications, precision industrial components, firearm finishes, and medical applications. Currently, we have 90+ Facilities around the globe that offer coatings with HEF-designed and -manufactured equipment, featuring proprietary technology that ensures high deposition rates while maintaining low deposition temperatures, uniform and precise coating thickness, and excellent coating adhesion.

The Science Behind DLC

High-performance components—from jet engines to precision molds—face extreme heat, friction, and corrosion. HEF NA protects them with diamond-like carbon (DLC), a thin but powerful coating that reduces wear, lowers friction, and extends part life.

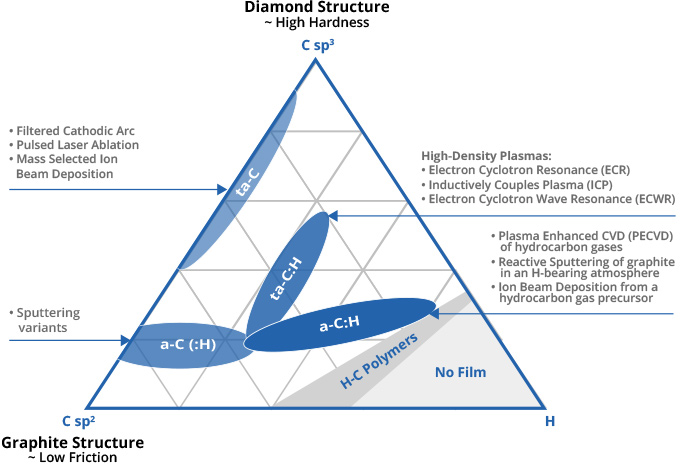

Ultra-hard, ultra-smooth, and chemically stable, DLC comes in tailored variants like hydrogenated and tetrahedral DLC to meet specific needs. Its low friction and heat-resistant finish minimize wear without lubrication, keeping components running longer and more efficiently.

Advantages of DLC Coatings

Engineered for performance and precision, DLC coatings deliver unmatched durability, making them ideal for high-performance, precision applications.

- High hardness (2500-4500 HV)

- Excellent wear resistance

- Friction reduction

- Thin, uniform film (precision coating)

- Excellent aesthetics

Our DLC coatings family combines the extreme hardness of diamond with the low friction coefficient of graphite, offering a unique balance of durability and lubricity. The performance characteristics of DLC depend on:

- Deposition technology & parameters

- Alloying elements

- Coating architecture – single, multilayered, graded, and customizable.

DLC coating isn’t just tough—it also has great load-bearing capabilities, making it perfect for boosting the performance of engineered components. In addition, these coatings are usually biocompatible so they’re safe for food contact and medical applications. Their smooth, low-friction surface also helps with easy release, making them a good choice for plastic processing applications.

DLC coatings can be applied using a variety of techniques and can be combined with elements like hydrogen or metals like chromium. The choice of materials and the deposition method play a big role in shaping the coating’s properties and overall structure.

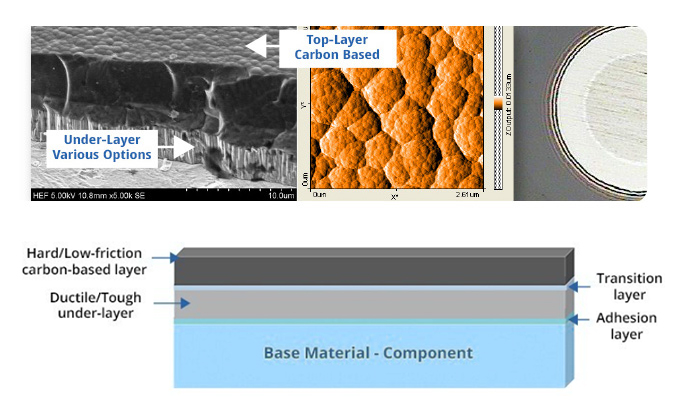

To handle the tough conditions in automotive and industrial applications, HEF NA has developed a range of DLC coatings. These coatings are made up of multiple layers, including materials like chromium (Cr), chromium nitride (CrN), tungsten (W), and tungsten carbide–carbon (WC-C), with a top layer of hydrogenated carbon.

The choice of the under-layer depends on several factors, such as: adhesion requirements, wear mode, contact mode, friction regimes encountered during operation, load-carrying capacity, and other metallurgical considerations.

Our DLC Coatings:

Commercial Name | Thickness | Maximum Use Temp | |

|---|---|---|---|

CERTESS CARBON DDT | <5 microns | 300°C (572°F) | More |

CERTESS CARBON DT | <5 microns | 400°C (752°F) | More |

CERTESS CARBON DCX | <5 microns | 300°C (572°F) | More |

CERTESS CARBON DCY | <5 microns | 300°C (572°F) | More |

CERTESS CARBON DCZ | <5 microns | 300°C (572°F) | More |

CERTESS CARBON TC | <3 microns | 350°C (662°F) | More |

HEF NA offers several other application-specific DLC Coatings.

Other DLC coatings can be customized based upon the unique combination of wear mode, contact mode and the friction regime under which the component is operating.

Contact Us