TESCO®

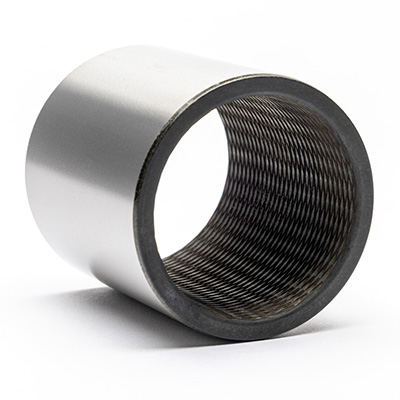

A TESCO sleeve bearing is manufactured from alloy steel with a core hardness higher than 50 RC, and a thermochemical surface treatment that imparts a case hardness higher than 800 HV. The surface treatment contributes excellent frictional properties and scuffing resistance, along with high surface hardness, even at sustained run temperatures up to 500°C.

The TESCO high-temperature sleeve bearing is ideal for both oscillation and rotation, and for applications that involve high loads. In addition to high-temperature bushings, Tesco treatments from HEF are available for pins, rollers, slides, screws and other complex parts.

Mating Shaft:

For optimal performances of the joint, the surface roughness should be inferior to 0.8 μm Ra. Shafts hardened for 56 to 60 HRC are recommended. HEF propose TESCO HT pins.

Note: lubrication of a TESCO high temperature sleeve bearing greatly enhances technical performance. For information regarding high-temperature greases, contact HEF.

Material Properties

- Type: Metallic

- Water Absorption (24h): 0%

- Housing: h7 (0.000984 in)

- Shaft Tolerances: f7 (ISO 286 standard)

- Optimal Shaft Roughness: Ra < 0.8 µm (Ra < 32 µin)

Temp. Ratings

- Low Temp: -40°C (-40 °F)

- Max Temp: 500°C (932°F)

- CTE: 1.2 E-5 /°K (6.67E-06 /°F)

Performance Limits

- Dynamic Load: 100 N/mm2 (14,504psi)

- Max Speed: 1.5 m/s (4.92 ft/s)

Applications

Recommended applications include, but are not limited to the following:

- Caster Segments

- Cooling Chain Bushings

- Dummy Bar Holding Systems

- Feeding System Cement Bags

- Ladle Metallurgy Valves

- Mandrel Slides

- Steel Plant Wheel Loaders

- Transport Screws

- Yarn Guides

Industries

This bushing is a popular solution for the following industries:

- Cement

- Glass

- Steel

Advantages

Advantages include, but are not limited to the following:

- Seizure and Wear Resistant