Excellence Engineered for Performance

HEF North America’s surface technologies and products are innovated for industries that require the highest levels of performance.

Watch VideoWelcome to HEF North America: Uniting Excellence in Coatings and Surface Technologies

HEF North America (HEF NA) unites a network of leading surface technology and coating providers under one brand, strengthening our ability to deliver advanced solutions that enhance performance, durability, and efficiency across industries. Integrating decades of experience and specialized capabilities enables HEF NA to offer seamless, comprehensive solutions.

Customers benefit from expanded expertise, streamlined processes, and a stronger network focused on high-quality solutions. With HEF NA you gain a strategic partner committed to advancing technology and performance. Discover innovation and integration with HEF NA—where expertise meets excellence.

18 Locations

across the U.S., Mexico, and Canada

Millions

of components coated annually

500+ Multinational Clients

rely on our coatings

70+ Years

of expertise in component coating

Innovative Solutions That Maximize Performance and Durability

DLC Coatings

A combination of PVD and PECVD technology, offering extreme hardness from diamond-like crystals and lubricity from graphite structures.

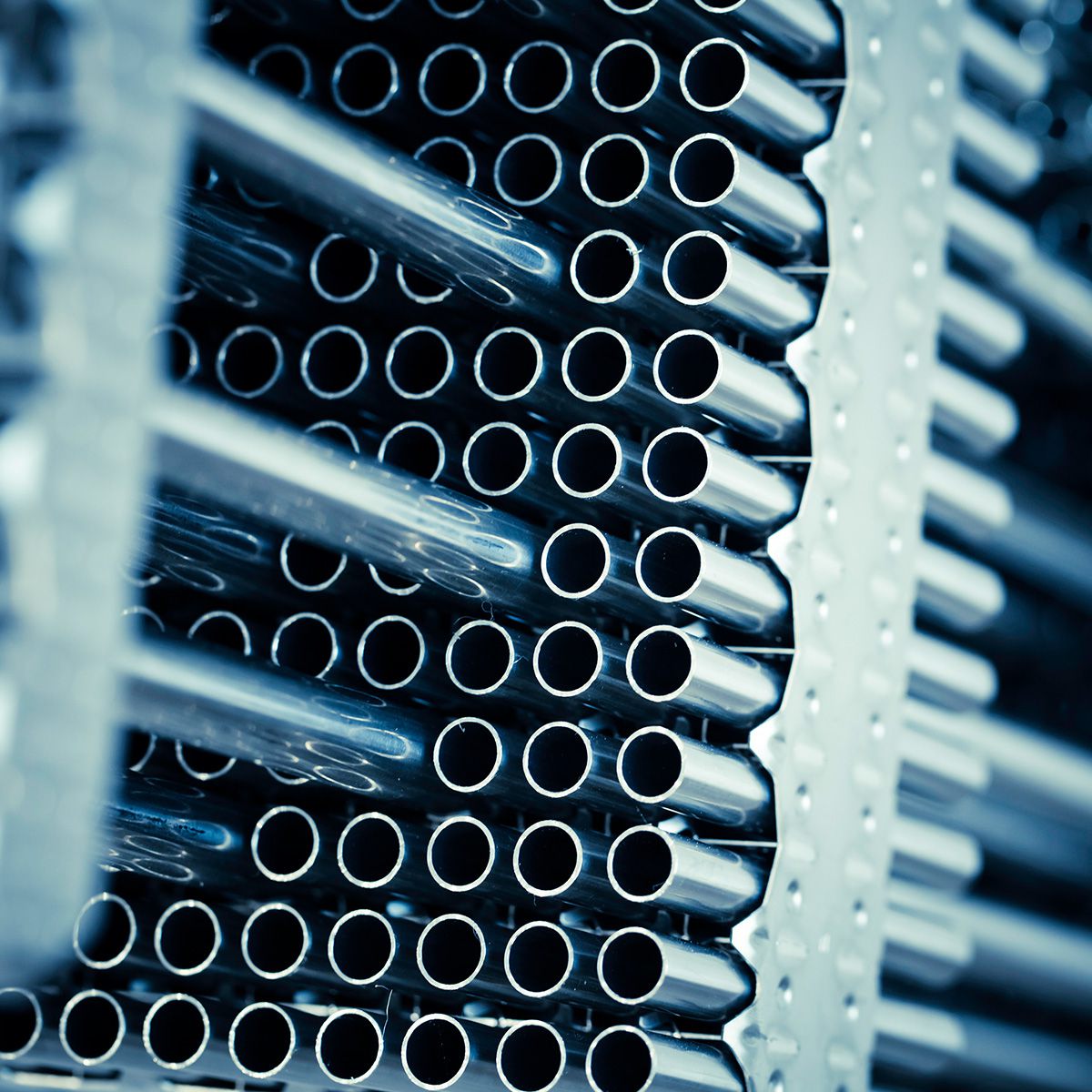

PVD & PECVD Coatings

Precision-engineered for extreme durability, providing enhanced wear resistance, friction resistance, hardness, and corrosion protection across a variety of industrial applications.

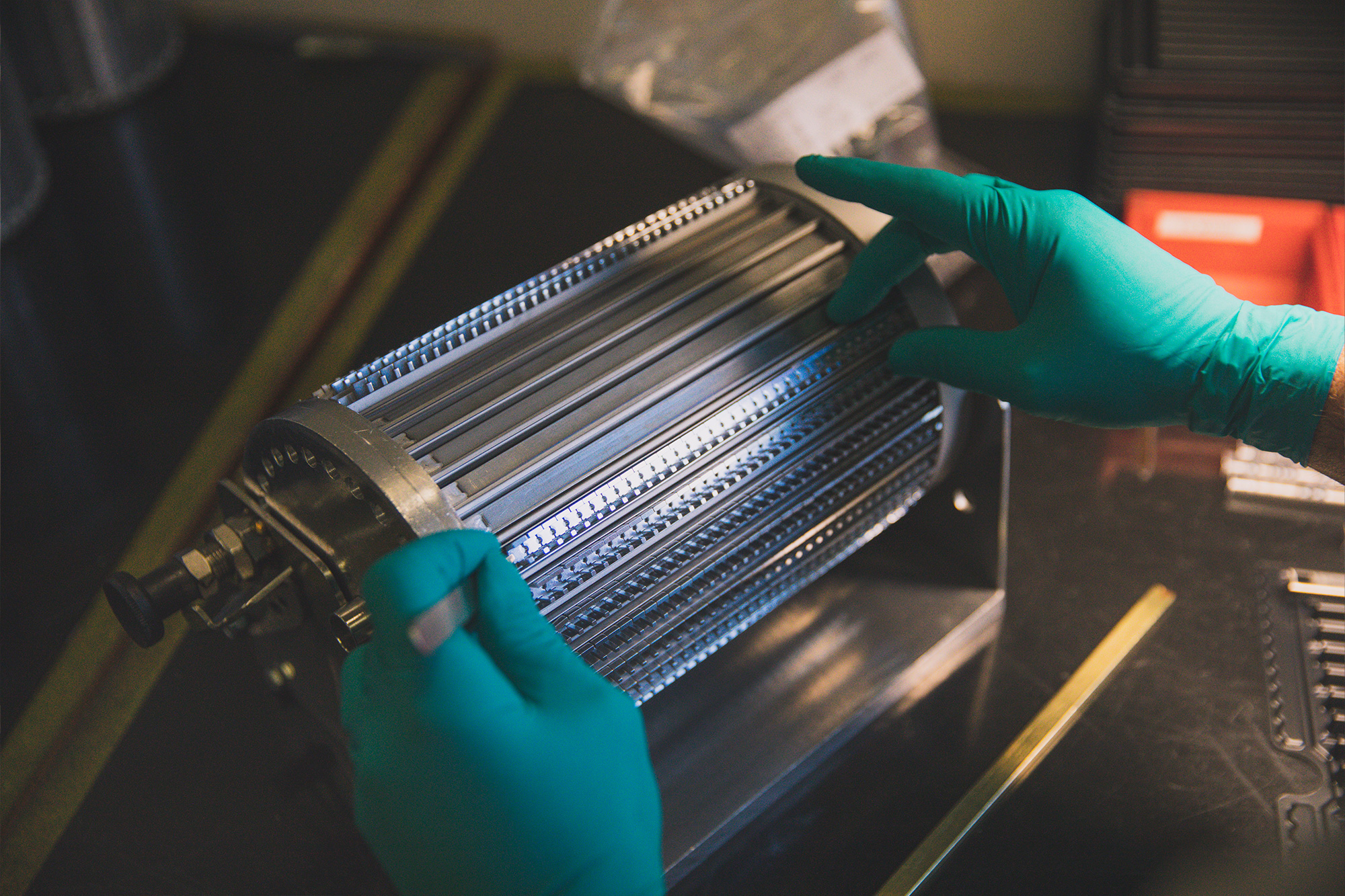

Liquid Nitriding

An advanced surface hardening process that diffuses nitrogen and carbon into metal, creating a wear-resistant and fatigue-resistant layer without compromising core strength.

Nickel & Chrome Plating

Offers superior corrosion resistance and aesthetic appeal, providing both functional and decorative finishes for a wide range of components.

Teflon™ Fluoropolymer

Delivers exceptional non-stick and low-friction properties, improving performance in high-temperature and chemical-resistant environments.

Manganese Phosphate

A crucial pretreatment that enhances adhesion, improves corrosion resistance, and reduces friction in moving components.

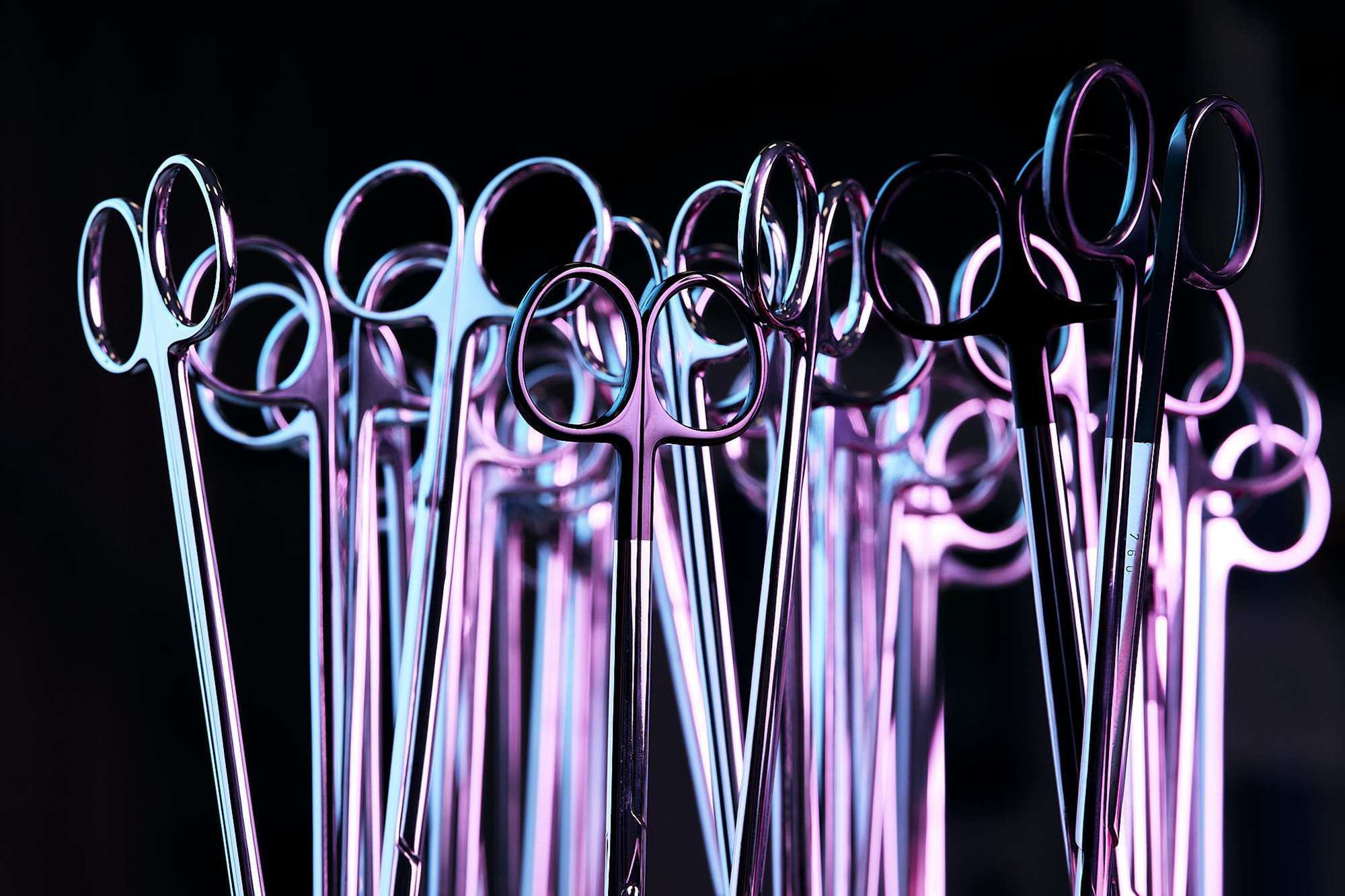

Engineered Bushings

Precision-designed for durability, these components minimize friction and wear, enhancing performance in demanding industrial applications.

Salt

Used in molten form for rapid, uniform heat treatment and heat transfer processes, these coatings prevent oxidation while offering high thermal stability, conductivity, and efficient heat storage at elevated temperatures.

Tribology Testing

We ensure your coatings deliver optimal wear resistance and friction performance by precisely analyzing surface interactions to develop durable solutions that extend component life and reliability.

Learn MoreGlobal Leader in Surface Materials Engineering

70 Years

of Expertise

$351 Million

Sales Revenue in 2025

3200

Employees

21 Countries

with Direct HEF Operations