Dry Film Lubricants

Intermittent Dry Lubrication to Withstand Extreme Conditions

Dry Film Lubricant coatings are designed to reduce friction and wear without the need for liquid lubricants like oil or grease. These coatings create a solid, low-friction surface, providing intermittent dry lubrication and helping protect moving parts in high-load, high-temperature, or extreme environments where traditional lubrication may fail.

Typically, dry film lubricants are made from materials such as molybdenum disulfide (MoS₂), graphite, PTFE (Teflon), or tungsten disulfide (WS₂). They work by forming a thin, durable layer that prevents direct metal-to-metal contact, reducing wear and extending the lifespan of components.

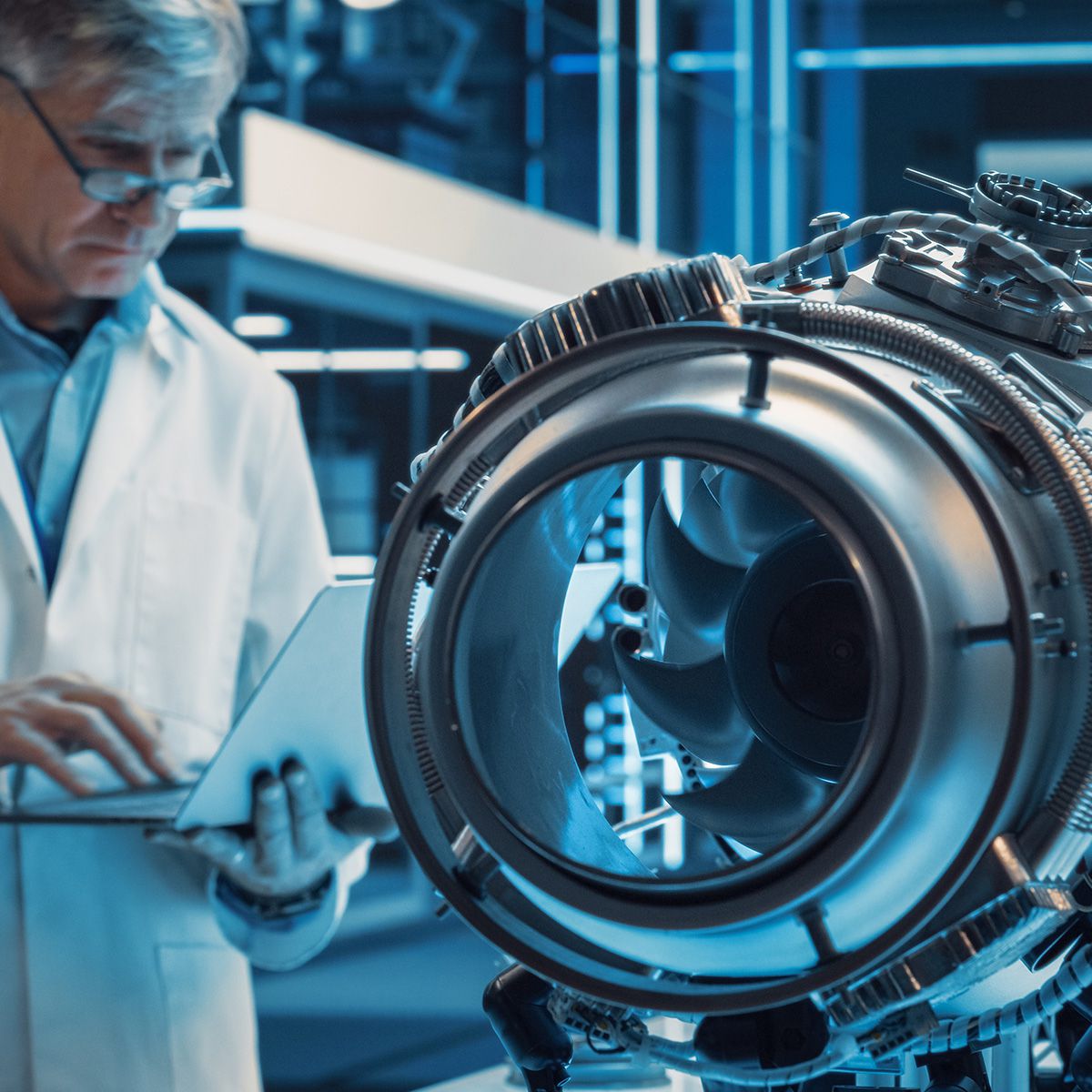

Common applications include aerospace, automotive, industrial machinery, firearms, and medical devices, where long-lasting, maintenance-free lubrication is essential. Dry Film Lubricant coatings are especially useful in situations where dust, dirt, or extreme conditions make liquid lubricants impractical.

Process Overview

Our Dry Film Lubricant coatings are applied as a spray process. Different surface preparation methods appropriate for the substrates will be used prior to the coating process. Coating thickness is varied to suit the application. Typical coating thickness can range from .00025″ to .002″.

Advantages of Dry Film Lubricant Coatings

These coatings offer a range of benefits that enhance performance and durability in demanding applications, providing reliable protection and reduced friction without the need for liquid lubricants.

- Provides intermittent dry lubrication

- Not affected by dust or dirt

- Corrosion protection

- Increased lubricity

- Low coefficient of friction for reduced drag and parasitic load

- Thin coating to accommodate assembly constraints

- Chemical resistance and corrosion protection

Our Dry Film Lubricants:

HEF NA offers several other application-specific Dry Film Lubricants.

For additional details, please contact us.

(704) 483-2202