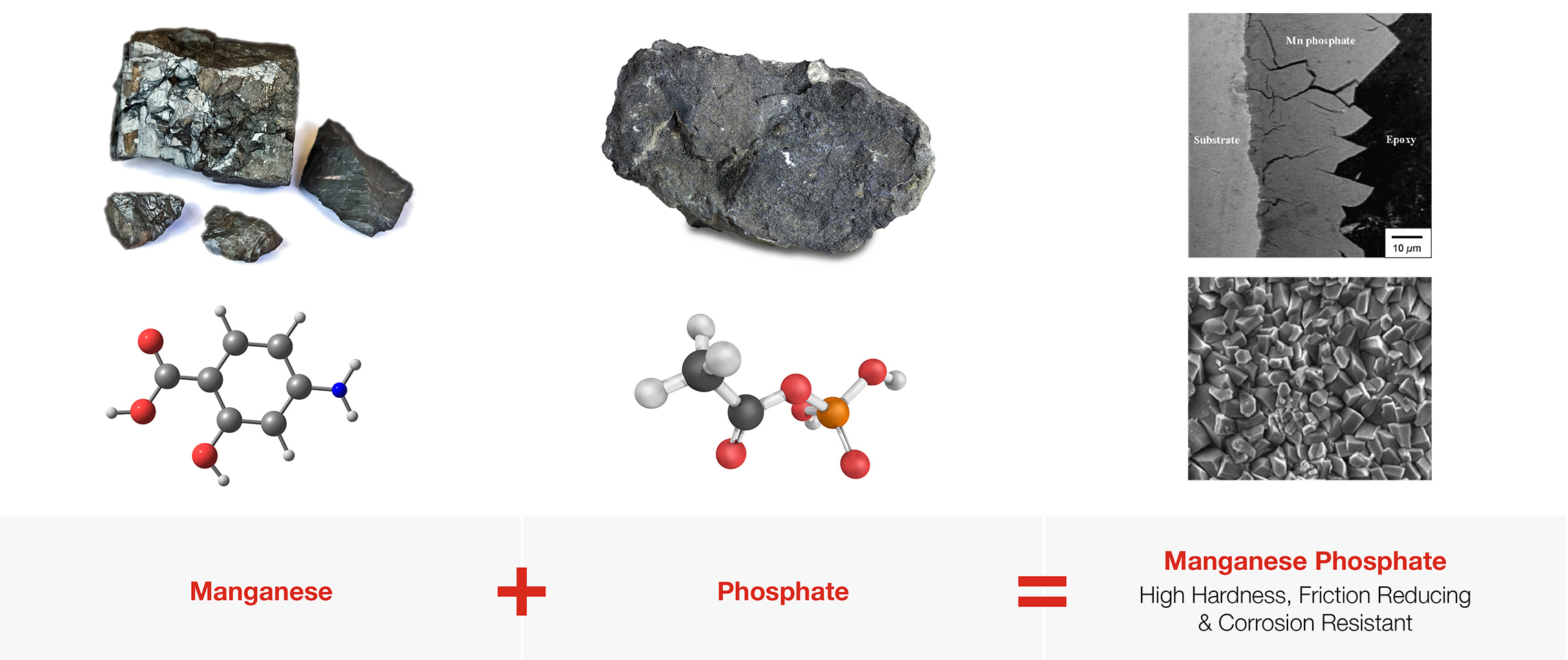

Manganese Phosphate

Wear Protection and Break-In Lubrication for High-Friction Metal Parts

Manganese Phosphate is a high-performance conversion coating applied to metal surfaces, renowned for its exceptional anti-corrosion and wear resistance properties. Commonly known as Parkerizing, our Manganese Phosphate application process reduces friction and enhances corrosion resistance, offering a protective coating solution for ferrous metal components.

Unlike many other coatings, Manganese Phosphate continues to provide protection to parts subjected to wear, even after the initial break-in period. This makes it the preferred choice for industries where components face significant wear and friction, including automotive parts, firearm barrels, industrial machinery, and military equipment—environments where durability and performance are paramount.

Phosphate produces a fine crystalline coating that can be applied to almost any ferrous metal component, such as subsea parts, tubular goods, threaded components, valves, fasteners, and connectors. Coating weight typically ranges from 2000 to 3500 mg/ft², depending on factors such as material composition, hardness, and the concentration, time, and temperature of the application process.

Process Overview

Manganese Phosphate is applied by immersion in a concentrated, heated bath, chemically converting the surface of the metal to an integral protective layer of insoluble phosphate crystals. The application of Manganese Phosphate involves a multi-step process designed to create a durable, corrosion-resistant coating on metal surfaces.

- Surface Preparation – The metal surface is cleaned and often pickled with an acid solution to remove oxides and contaminants.

- Immersion in Manganese Phosphate Bath – The part is submerged in a heated bath containing manganese phosphate salts, typically at temperatures around 190–210°F (88–99°C).

- Chemical Reaction – A reaction occurs between the metal and the phosphate solution, forming a crystalline Manganese Phosphate layer on the surface.

- Post-Treatment – The coated part is often oiled or sealed to enhance corrosion resistance and improve lubrication properties.

Advantages of Manganese Phosphate

These advantages make Manganese Phosphate coatings a popular choice for enhancing the performance and lifespan of metal components in industries ranging from automotive to machinery.

- Corrosion Protection – They form a protective barrier on metal surfaces that helps resist rust and corrosion by shielding the substrate from moisture and aggressive environments.

- Enhanced Lubrication & Wear Resistance – Their porous structure retains lubricants effectively, reducing friction and minimizing wear in moving components.

- Improved Adhesion – The coating creates a textured surface that significantly improves the bond strength of subsequent paints, oils, or sealants.

- Cost-Effective Durability – This conversion coating is an economical solution that boosts the longevity and performance of metal parts without a significant increase in processing costs.

- Versatility – Suitable for a variety of metals and industrial applications, enhancing fatigue life and overall durability in diverse environments.

Our Manganese Phosphate Coatings:

HEF NA offers customizable Manganese Phosphate Coatings through Calico Coatings.

For more details contact Calico Coatings.

(704) 483-2202