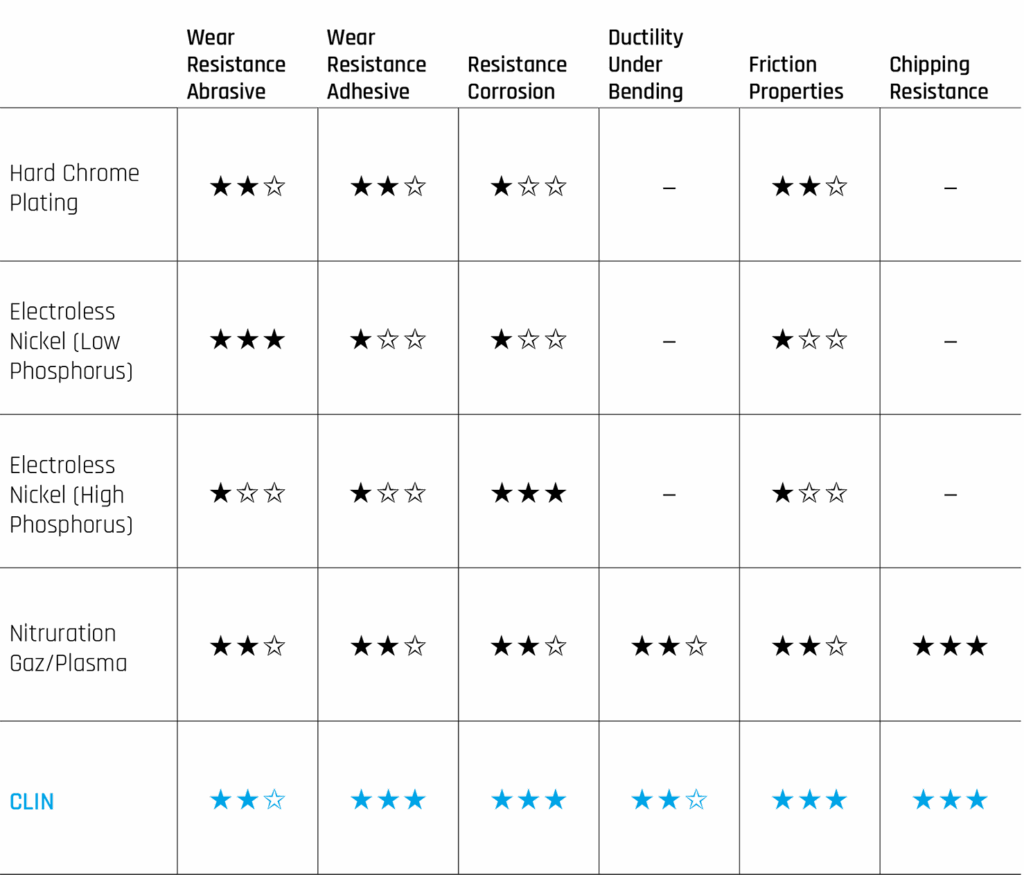

HEF NA’s nitrocarburizing treatments are patented and marketed under the names ARCORTM, SURSULFTM, TENIFERTM, TUFFTRIDETM, MELONITETM, NUTRIDETM, and QPQTM—all grouped together under the name CLINTM.

These treatments are supplied by HEF through its international TECHNIQUES SURFACESTM network or integrated at the customer’s site, depending on the project. Moreover, CLINTM processes emit no volatile organic compounds (VOCs) or nitrogen oxides (NOx), use no PFAs, and are REACH-compliant.